In the sH2unter@ports project, the stakeholders are analysing the extent to which the infrastructure needs to be adapted to low-emission drives. Basically, there are several options in the port areas being analysed, such as operating the locomotives using electrification via overhead lines and batteries or hydrogen propulsion. This means that the infrastructure in the harbour must be expanded accordingly.

Refuelling with hydrogen

• Hydrogen production

Water can be split into oxygen and hydrogen. In this way, electrical energy can be converted into chemical form (power-to-X, or PtX for short). Depending on how the electricity is produced, hydrogen also has different indirect effects on the climate and the environment. The different production methods of hydrogen are symbolised with colours:

• Hydrogen supply

Hydrogen can be transported in various forms. Even if hydrogen supply via pipeline systems is conceivable in the future, the demand for hydrogen for the shunting locomotives can be met by delivery via road transport.

Initially, when the demand is still low, a mobile solution is also conceivable, as various suppliers deliver interchangeable systems by truck, which require little expenditure in terms of space, planning and permits.

In the long term, shunting locomotives can be fixed, plannable consumers for a hydrogen filling station, which should be designed for different types of vehicles if possible (multimodal hydrogen filling station).

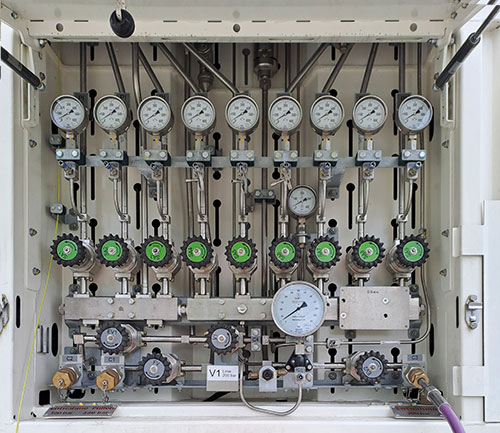

• Hydrogen storage

Hydrogen is stored under different pressures, gaseous or cryogenic. Gaseous hydrogen is currently compressed to 350 bar or 700 bar (CGH2 – Compressed Gaseous Hydrogen) for refuelling vehicles. Currently, these forms of storage are the most common. But other options are also used: Liquid hydrogen is stored at approx. -253°C, at 3 bar (LH2 – Liquid Hydrogen), or compressed to up to 16 bar at approx. -247°C (sLH2 – Subcooled Liquid Hydrogen). There is also cryocompressed hydrogen, cooled to -240°C and up to 350 bar (CcH2 – Cryo Compressed Hydrogen).

• Refuelling

Currently, hydrogen is often used for refuelling in gaseous form at various pressure levels. Refuelling a train is a challenge, because the flow rate must be large for rapid refuelling. Germany’s first hydrogen fuelling station was inaugurated in Bremervörde in 2022. There, the regional train is refuelled by the project partner and rail transport operator evb. The iLint train, built by locomotive manufacturer Alstom, refuels here. Two 100-litre tanks are filled at 350 bar. Once refuelled, the passenger train can travel over 800 km. Much of the experience gained here is being incorporated into the sH2unter@ports research project.