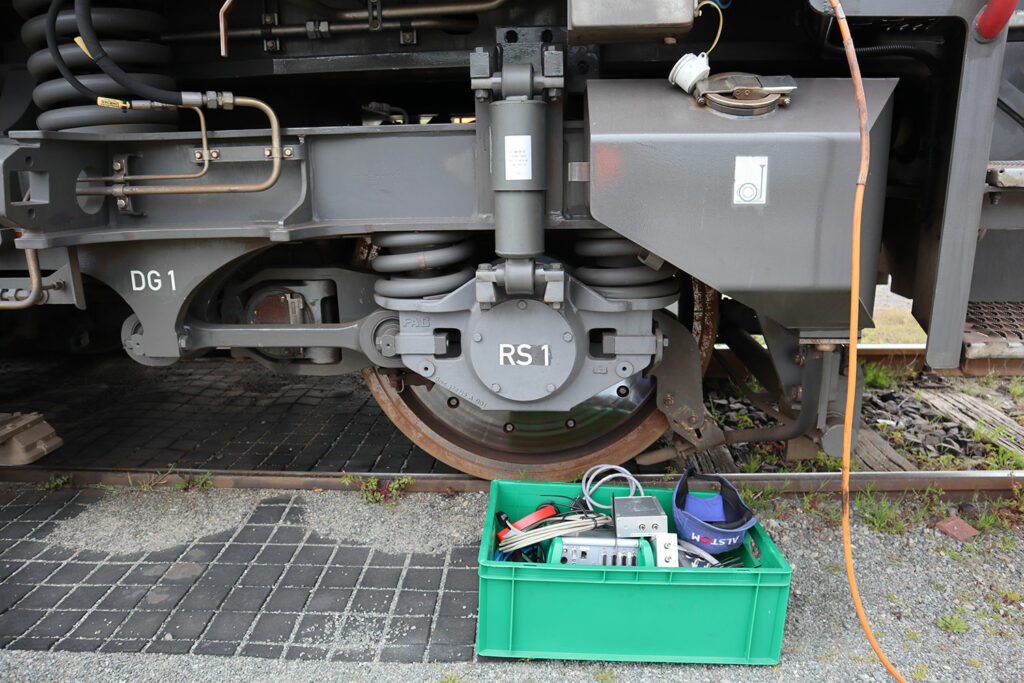

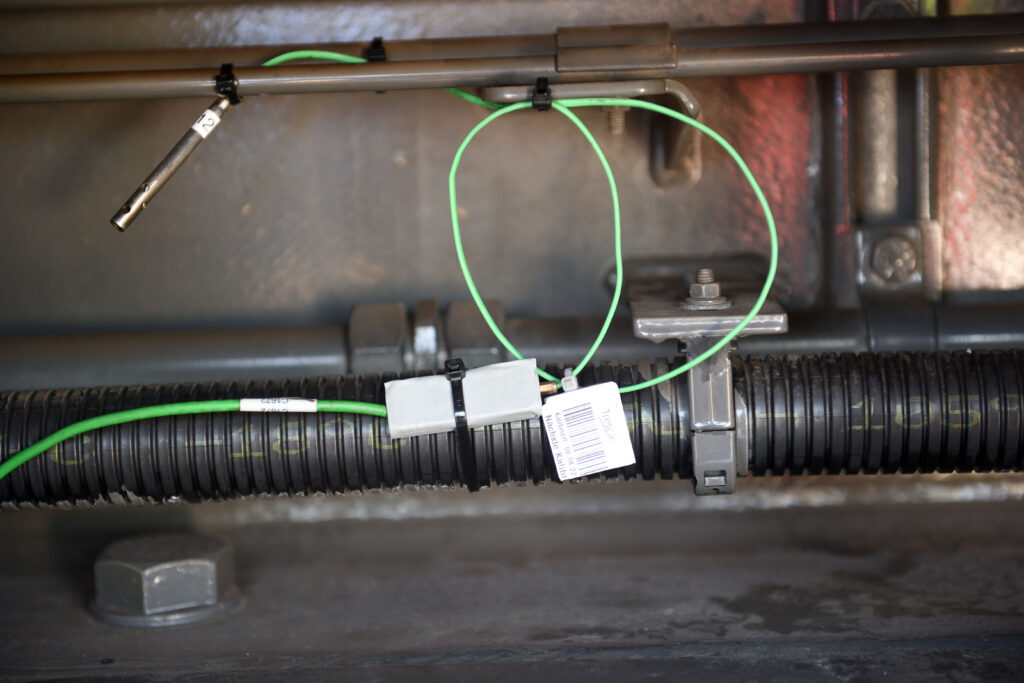

In the sH2unter@ports study, the performance requirements for shunting locomotives in harbour areas are being closely examined. A conventional G1000 diesel locomotive was equipped with measuring sensors to investigate the exact power utilisation. How much power the locomotive needs is determined, among other things, by the total weight of the attached loads, the acceleration during operation and the profile of the route network in the harbours, as the approach energy increases many times over even on small hills. The type of operation also plays an important role, as the operational process must not be disrupted by long or frequent refuelling or loading times.

The test runs in the seaports were completed at the end of September 2023 and the data was used to design different locomotive variants.

Analysed variants for future shunting locomotives

1. Conversion of an existing locomotive

Shunting locomotives are powerful locomotives that are built for a long service life. The average age of existing locomotives in Germany is over 40 years. The stock of locomotives was partially increased 10 years ago. These locomotives have at least 30 years of service life ahead of them, but are equipped with conventional combustion engines (Pagenkopf et al., 2022). With the demand for sustainability and resource efficiency, alternatives to new construction must be found, as a complete replacement of the existing ‘fleet’ is currently neither economical nor ecological. For this reason, one of the research interests of the sH2unter@ports project is to investigate the conversion of diesel locomotives to hydrogen-based drives. Retrofit models with an H2-combustion engine were pursued in the study.

The project partner Alstom presented a prototype 2022.

2. Construction of a new shunting locomotive

In the medium term, there must be concepts for the new construction of climate-neutral, efficient shunting locomotives. Fuel cells are the future-oriented innovation for new designs, as the drives have low energy losses and are more efficient than combustion engines.

The manufacturer Alstom is developing a 4-axle hydrogen-powered locomotive based on the TRAXX SHUNTER plattform a 4-axle hydrogen-powered shunting locomotive with fuel cell propulsion, which can be used for heavy shunting operations in ports and industrial plants in Europe from around 2027.

At the same time, locomotives with overhead line and battery systems are also being developed so that they can run on uncovered areas.

If you have any questions, please contact Mr Jörg Schulze at Alstom.

3. Conversion to alternative fuels

Fuels can be chemically produced, i.e. synthesised. The compounds of carbon and hydrogen can be put together in many different ways, for example synthetic diesel or synthetic methanol already exist. However, these substances are extremely energy-intensive to produce.

Another alternative is already being used in Bremerhaven’s overseas port: since March 2023, the locomotives have been refuelled with hydrogenated vegetable oil (HVO). When HVO is burnt, CO2 is released that was previously absorbed from the atmosphere by the plants. This is why it is considered climate-neutral. The use of HVOs is a short-term solution. One advantage is that it can be used quickly, but its long-term and widespread use is questionable due to the large amount of resources and land required to provide this ‘biodiesel’.